Engine Turning the HillBilly Way

Posted: October 18th, 2012, 3:06 pm

I wanted an engine turned look for my aluminum parts, but didn't want to use adhesive film: it doesn't look real and is not 1/4 scale.

So I ordered CRATEX ABRASIVE sticks from MCS Industrial Supply Co. in 3/16 and 1/4 diameter sizes. They are 6" in length and last forever. If you try this at home too - buy only one. (PN 03202975 3/16) (PN 03192150 1/4). I used about 1/4 inch of one stick, so I'm good for a lifetime.

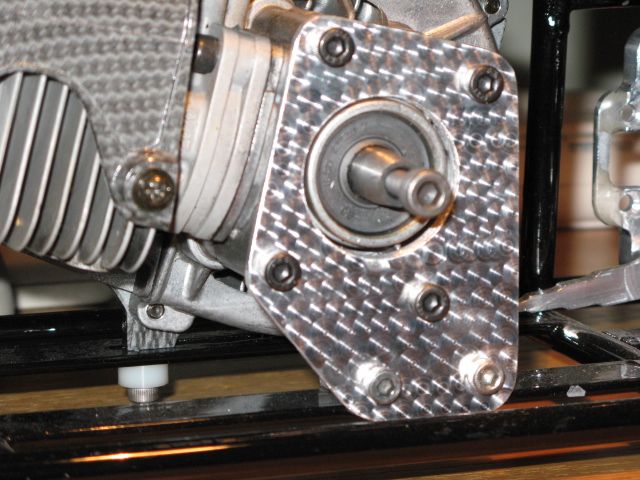

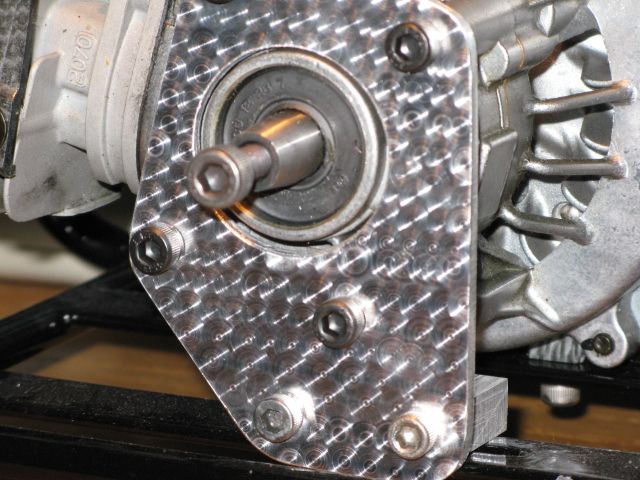

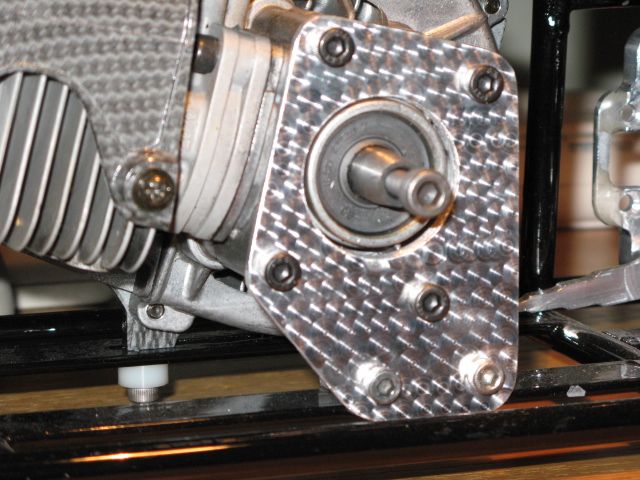

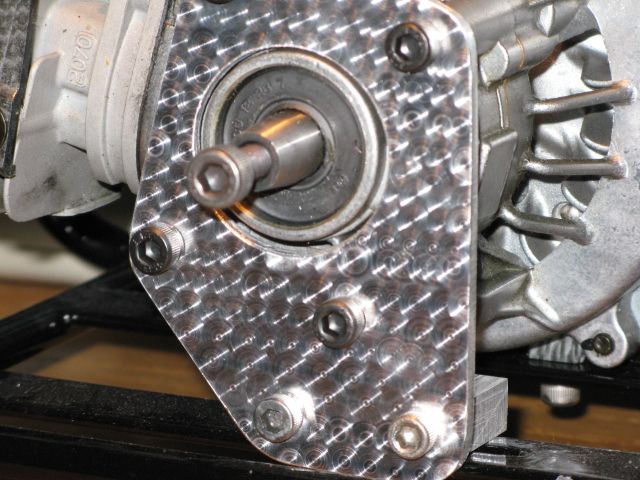

Here's some examples of 1/4" dia. engine turned parts (1" to scale).

I fabricated the parts from 3/16 aluminum sheet; sanded them with a DA sander, wet sanded them; polished them and then loaded them into an indexing jig I made to get the correct overlap for each row of the pattern in the drill press.

I set the drill press at 640RPM and started turning. A CNC milling machine would have come in handy here, but once you get the feel of it, the rows go by pretty quick by hand. Each part took only 15-20 minutes, once they were set up. Getting each turn with the exact same pressure is the key. Not sure I accomplished this, but I came pretty close.

The photos don't do it justice; it looks great out in the sun.

So I ordered CRATEX ABRASIVE sticks from MCS Industrial Supply Co. in 3/16 and 1/4 diameter sizes. They are 6" in length and last forever. If you try this at home too - buy only one. (PN 03202975 3/16) (PN 03192150 1/4). I used about 1/4 inch of one stick, so I'm good for a lifetime.

Here's some examples of 1/4" dia. engine turned parts (1" to scale).

I fabricated the parts from 3/16 aluminum sheet; sanded them with a DA sander, wet sanded them; polished them and then loaded them into an indexing jig I made to get the correct overlap for each row of the pattern in the drill press.

I set the drill press at 640RPM and started turning. A CNC milling machine would have come in handy here, but once you get the feel of it, the rows go by pretty quick by hand. Each part took only 15-20 minutes, once they were set up. Getting each turn with the exact same pressure is the key. Not sure I accomplished this, but I came pretty close.

The photos don't do it justice; it looks great out in the sun.